Projects

Check out some of our successful developement and supply chain management projects

Success Stories

Mfgbooster Eliminates Supply Chain Uncertainty

Challenge: A U.S. consumer products company that designs and sells exhibition display solutions was having vendor issues that resulted in lead times being pushed out up to a year for their products. This put them in a bind as demand continued to grow, resulting in a growing strain on internal resources. They didn’t have the time or expertise needed to get their supply chain under control.

Solution: After meeting with the customer’s supply chain team and mapping out their logistical and vendor issues, Mfgbooster was able to develop a complete supply chain solution that brought the customer’s product lead times back within expectations. Mfgbooster pivoted resources to quickly source a new production factory partner, get samples produced and approved by all parties, and deliver their first order faster than expected. With all customers, Mfgbooster provides weekly updates every step of the way to keep communication and visibility at the forefront.

Mfgbooster Creates Alternative Sourcing Solutions

Challenge: An American manufacturer of fluid power products was overwhelmed by disruptions to production as their factory was relocating from the Northeast U.S. to the South. Furthermore, their supply chain department was tasked with continuing operations during the significant move with minimal disruption to their client base.

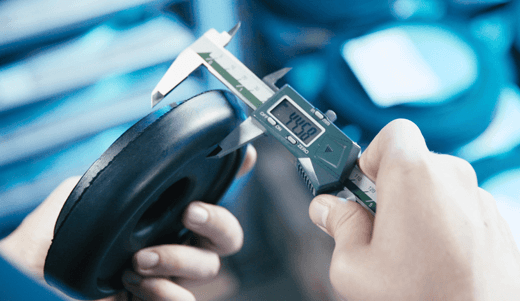

Solution: During their transition, they reached out to Mfgbooster to manufacture some important machined iron castings that they had trouble finding a manufacturing solution for themselves. The facility that Mfgbooster found to do the work had to be able to tool up, produce approval samples, and run production quickly, all the while maintaining strict dimensional tolerances. Our team was able to deliver by having their parts quoted and in production before any disruptions occurred in their services to clients. The client stayed informed of our progress throughout the process allowing them to accurately meet customer demand.

Mfgbooster Partners with Customer to Improve Product Design and Performance

Challenge: A Midwest manufacturer specializing in early childhood learning products reported a product failure in the field, initially attributing the failure to a missing weld. After Mfgbooster’s investigation and extensive testing, our team also found a significant shortcoming in the design. After notifying the customer, Mfgbooster developed a plan to resolve the issue themselves.

Solution: Mfgbooster worked with the factory and the customer to revise the design, update the drawings, and test the new solution. To overcome limited warehouse space for a rework effort, ITI also reworked the existing inventory at a 3rd-party facility by replacing the affected parts with redesigned parts and repackaging the product in the original packaging. Mfgbooster was able to complete the evaluation, design, testing, production, rework, and repackaging all in a few short months, while also using few of the customer’s limited existing resources.